Printed circuit boards (PCBs) play a vital role in the medical, aerospace, and automotive industries, among others. Because PCBs are involved in high-tech, high-risk situations, you’ll want to ensure your manufacturer has effective printed circuit board quality control processes. Consider these items before signing on with a PCB manufacturer.

Printed Circuit Board Quality Control Tests

There are quite a few tests used to ensure PCB quality. Implementing these tests can catch faulty product before it reaches consumers, mitigating your business’ liability. While this is by no means an exhaustive list of PCB testing procedures, you’ll want to make sure your chosen manufacturer has these capabilities.

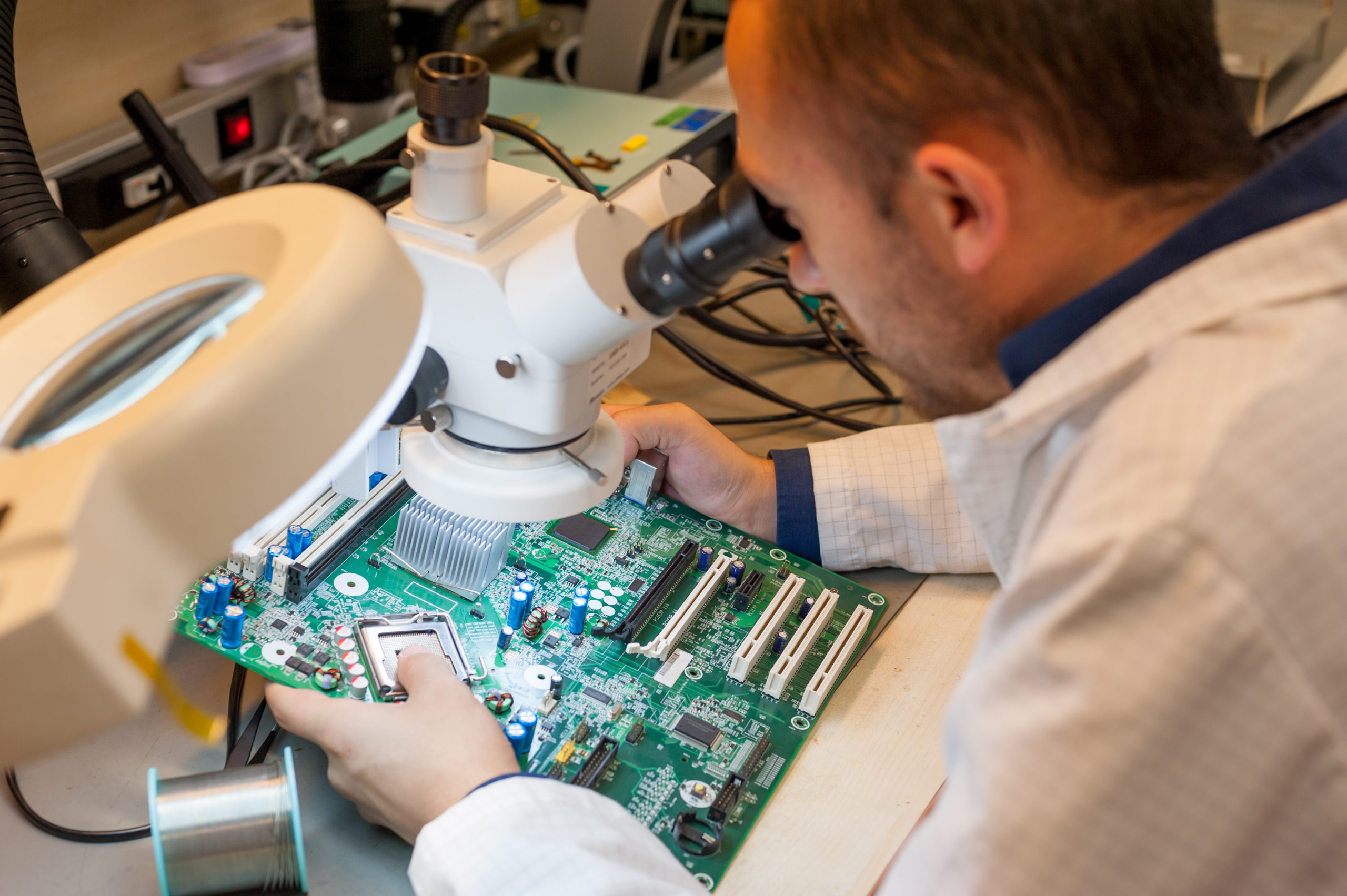

3D Optical Inspection

A 3D optical inspection is a form of automated visual inspection that uses cameras to take photos of the PCB. The program will then compare the images to a detailed schematic. If a PCB does not match the schematic to a certain degree of accuracy, a technician will flag it. This kind of inspection is helpful as it can detect issues early and ensure production is shut down as soon as possible to mitigate wasted time and money.

Burn-in Testing

Burn-in testing simulates the actual use of PCBs for long hours and ensures their reliability under the maximum specified stresses and loads. Burn-in testing pushes power through the board for anywhere from 48 to 168 hours, depending on its specification. This testing is crucial for detecting early failures. While burn-in testing isn’t necessary for every project, it can sometimes prevent potentially dangerous products from reaching customers.

X-Ray Fluorescence Testing for RoHS Compliance

X-ray fluorescence testing focuses on the parts of a product with the highest risk of containing RoHS substances, including cadmium, lead, mercury, and more. X-ray testing checks elements that a normal optical inspection might miss. This includes parts such as connections and ball grid array packages with solder joints located under the chip package.

Functional Testing

Your manufacturer uses functional testing to verify that your product will power up. The customer typically provides the parameters for this test, though some manufacturers can help develop and design it.

Certifications

Certain certifications given by the Institute for Interconnecting and Packaging Electronic Circuits (IPC), International Organization for Standardization (ISO), and the Food and Drug Administration (FDA) ensures manufacturers are making products to certain specifications. When you’re looking for a manufacturer to make your printed circuit boards, you’ll want to ensure the company has the following certifications.

ISO Compliance

ISO compliance comes into play during the printed circuit board quality control process for medical devices. If you’re looking for high-quality, consistent, medical-grade PCBs, you’ll want to find a manufacturer that follows these guidelines. At South Dakota Partners, we adhere to ISO 13485:2016 guidelines to ensure repeatable, quality PCBs, every time.

FDA Registration

The FDA imposes certain requirements on medical-grade PCBs, as well. These regulations pertain to the design, production, packaging, labeling, storing, fitting, and maintenance of medical devices. South Dakota partners is registered with the FDA as a medical device manufacturer.

Constant Research and Feedback Cycles

Production quality teams should always ensure their products meet or exceed the aforementioned quality and safety standards. These participants should include employees from the production, engineering, purchasing, and other departments as required. These teams should meet monthly to discuss quality trends, material issues, and supplier information or issues as well as reviewing the manufacturing processes.

Additionally, your manufacturer should use small focus groups from the same departments to address day-to-day issues found in the manufacturing or inspection processes. This will help them provide you accurate, up-to-date printed circuit board quality control information to you.

We’ll Help Design and Perform Your Printed Circuit Board Quality Control Process

At South Dakota Partners, our goal is to ensure you’re putting out the best quality products to reduce your business’ risks associated with supply chain inefficiencies, late delivery, or sub-par product.

We effectively manage your cost and lead times through efficient manufacturing processes, so you know your product will be delivered on-time without any issues.

If you’re looking for an electronics manufacturing company to help you with printed circuit board quality control, our team is ready and eager to work with you. Reach out to us today to schedule a meeting.